Early Bird Offer! Free tickets to meet independent experts at this summer's Build It Live

Save £24 - Book Now!

Early Bird Offer! Free tickets to meet independent experts at this summer's Build It Live

Save £24 - Book Now!Now that we have received planning permission, our design team – Model Projects – has been hard at work arranging meetings with suppliers and manufacturers, as well as developing details for the key areas of my new home. Once the initial layout plans were confirmed, work started on the technical drawings.

James Hood – MD of Model Projects – explained to me that the design’s large spans, tall ceilings and overhangs were calling out for SIPs (structural insulated panels). His enthusiasm for this thermally efficient, modern method of construction led me to undertake my own research. I soon became convinced that it was the only route forward for this project.

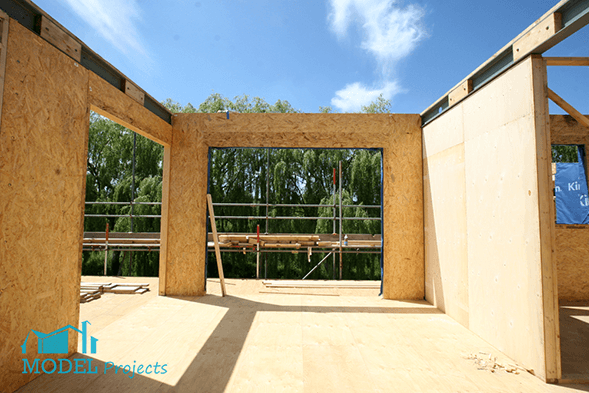

We are using Kingspan TEK panels from Potton; these consist of a high performance insulation core, sandwiched between two layers of oriented strandboard (OSB). During manufacture, the insulation core is autohesively bonded to the OSB facings. The panels are the structural loadbearing element of the house and support floors, the roof and internal loads. It serves the same function as the blockwork inner skin in traditional masonry.

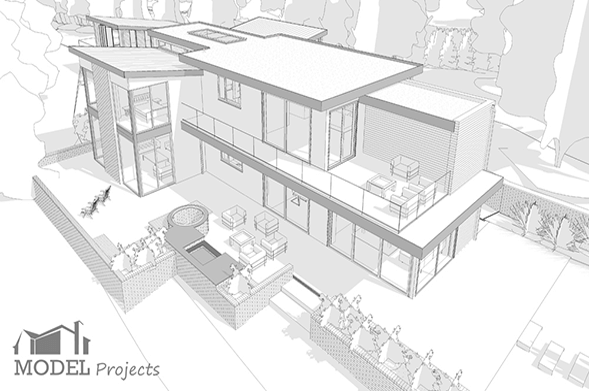

Model Projects worked closely with Potton’s engineers and technical department to ensure that the design intent was consistent. This included hiding any structural beams within the floor deck and ensuring the balcony and overhang remain dramatically projecting out towards the willow and stream.

James and the team use 3D home modelling technology, which has been a massive benefit with regards to the technical collaboration with Potton. The SIPs panels were cut directly from the drawings to ensure accuracy. From a personal point of view, these renderings helped me to visualise exactly how my new home would look, both internally and externally.

The panels are now starting to go up and the house is really taking shape. It’s excting to see the wall elements craned into place and we are delighted to have already achieved so much in such a short period of time.