Learn from the experts with our online training course!

Use the code BUILD for 20% off

Learn from the experts with our online training course!

Use the code BUILD for 20% offWhen it comes to specifying your external walls – and your ultimate choice of construction system – there’s a wide range of really credible options to choose from.

Each will have core benefits, which generally fluctuate around price, speed of build, performance, eco-friendliness and aesthetics. Getting the mix right for your project often takes lengthy debate and research.

Often referred to as traditional cavity wall construction, this is the most commonly used method of building houses in the UK and we’ll use it as our benchmark here.

Facing bricks are used on the outside skin and then lightweight blocks for the inside, which have both strength and thermal properties. When insulation is added to the wall, either in the cavity or as an extra layer on the inside (or both), it can provide a good overall performance.

Learn more: Does Blockwork Still Make Sense for Self Builders?

How well it functions depends on the type and thickness of both the lightweight blocks and the insulation.

A typical specification that would comply with the LFP of a brick-and-block external wall could be a 100mm facing brick, a 100mm mineral wool fully filled cavity, and a 100mm internal lightweight block with 15mm lightweight plaster.

Overall, for an average-sized project built to a standard self build specification, you can expect to pay from around £105 per square metre (m2) of basic brick and block cavity walling, including labour, insulation, wall ties and damp proof courses.

For a fully finished brick and block cavity wall, including the internal plastering, decoration and skirting, you’ll be looking at upwards of £150 per m2 for materials and labour.

You’ll then need to add the builder’s profit (say around 20%), which takes our indicative brick and block cavity walling costs to around £180 per m2.

Of course, the exact price you pay will vary according to the complexity of your project, size, specification, location etc.

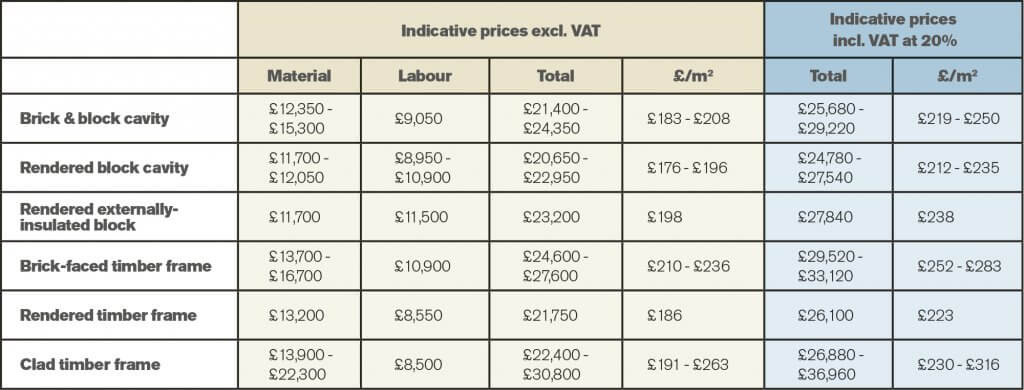

The table below shows a model cost guide to various walling systems.

These benchmark costs (courtesy of Andrian Wild from the Build It Estimating Service) are based on constructing a new house with a net wall area of 117m2.

They include options for different external claddings, including brick and render, as well as a comparison with using timber frame as the inner leaf (rather than blockwork).

The prices include: builder’s profit margin, labour, materials, finishes, insulation and internal plastering. The costs below do not include: windows and doors.

Self build projects qualify for zero-rated VAT on labour and materials (the latter reclaimed on completion), but renovators and extenders will usually need to pay the standard 20% rate on both aspects

When you start to consider some of the other options available it can be quite difficult to make financial comparisons against the benchmark of traditional brick-and-block construction mentioned above.

The common distinction with timber/metal frame, structurally insulated panels (SIPs), insulated concrete formwork (ICF) and thin joint blockwork as alternatives is that they are all substitutes for the inner skin and, with the exception of thin joint, the location of the insulation.

Additionally, for timber/metal frame and SIPs they will also need to be used in conjunction with a lighter weight intermediate floor structure.

Generally speaking these other options will cost you more, as they all add different performance levels. In most instances they will also save a considerable amount of time on site, something that should not be underestimated as a real cost saving.

Insulation is a fundamental element of a building’s design and it serves two purposes: its inclusion in our ground floors and external walls is for thermal reasons, while in our internal walls and intermediate floors it is for acoustic reasons.

To make matters more complicated, insulation with high thermal properties won’t be that good for acoustic performance, and vice-versa. This is because for thermal performance you need pockets of air (like a duvet, for example) and for acoustic performance you need density.

There are minimum standards for the thermal performance and air tightness of our external envelopes. More recently, new rules have been introduced to help regulate standards concerning sound reduction, especially with reference to joined terraced properties or flats.

Your designers will have to ensure that your specifications meet minimum levels of compliance, but this is rarely a problem with self-builders, who tend to try to exceed current standards in order to benefit from the extra performance that it delivers.

Part L1A of the 2010 Building Regulations calls for minimum ‘limiting fabric parameters’ (LFP) for each thermal element. Beware though, because if one part of your specification is on the low side, other areas may have to be upgraded to compensate for it.

This is because building control assesses thermal performance based upon minimising carbon emissions through the design as a whole, and not through minimum compliance of each thermal element.

The sliding scale of thermal insulation pricing starts with mineral wools and moves through to expanded polystyrene, and then on to foil-backed polyurethane (which has now been improved to combat the pollutant chemicals used in its production).

You can check live insulation prices online with suppliers such as Materials Market, Insulation Superstore and builder’s merchants.

As a rough guide, wool insulations can start from a few pounds per m2, with prices rising to around £20 per m2 for the best performing rigid board options in minimal thicknesses.

When it comes to acoustics, look for the denser insulation options – 24kg per m2 for walls and anything up to 100kg per m2 for intermediate floors.

My preference with timber-joisted floors is to use a really dense 30-40mm of acoustic insulation with a 19mm plasterboard plank sandwiched between two layers of flooring-grade chipboard; this combination deals brilliantly with both airborne and impact noise.

It’s a more expensive option for both materials and labour, and has to be thought through as a detail before you start building, but it’s well worth it if noise mitigation is important to you.

Tim Doherty’s article was originally published in 2013. It was updated on 27th April 2020 with the latest cost guidance, including prices from the Build It Estimating Service.

HI

Thanks for this info, but i must be misunderstanding something about the table you provide above – circa £30k for a house to have been built brick/block and including plastering??

Bricks could easily be £1 each so cicrca £10k on bricks alone, then blocks, and you say wall build costs of £80m2 that = £9360 just to have the brick and blockwork built.

What am i misunderstanding?

thanks

Hi Garry,

Thanks for bringing this to my attention.

The headline price of £80 per m2 Tim came up with in 2013 referred purely to the blockwork, insulation, external brickwork, wall ties and DPC. It did not include any plastering or sundries (such as cavity closers).

The examples in the Build It Estimating Service table just below were much more recent.

To that end, Tim has recently supplied some updated costs, which I’ve now integrated into this article.

Hopefully it makes more sense now!

Best wishes,

Chris Bates (editor, Build It magazine)

I am considering a build project consisting of 6 x 2 bed flats around 70sq m per flat

How much would each flat cost to build roughly?

Kind regards,

Paresh

What would the average cost be per square meter to build cavity wall 125 total square metres, )cavity to be closed with preformed cavity closers)..and do lintols, and cavity dpc trays have to be priced seperatley