Located on the largest self build development in the UK – Graven Hill in Bicester – Build It’s Self Build Education House is an access-all-areas project, where you can really get under the skin of what it takes to create your dream home.

Before even the sketch design phase, Build It approached Kloeber to come on board as its window and entrance door supplier. Editor Chris Bates was taken with the company’s strong product offering – including timber, aluminium and alu-clad solutions – and reputation for excellent customer service.

Kloeber’s Matt Higgs was heavily involved in the pre-build stages, providing invaluable advice on the glazing specification. The first major decision was to go for factory-painted, engineered softwood frames for the double-glazed windows, French doors and FunkyFront entrance.

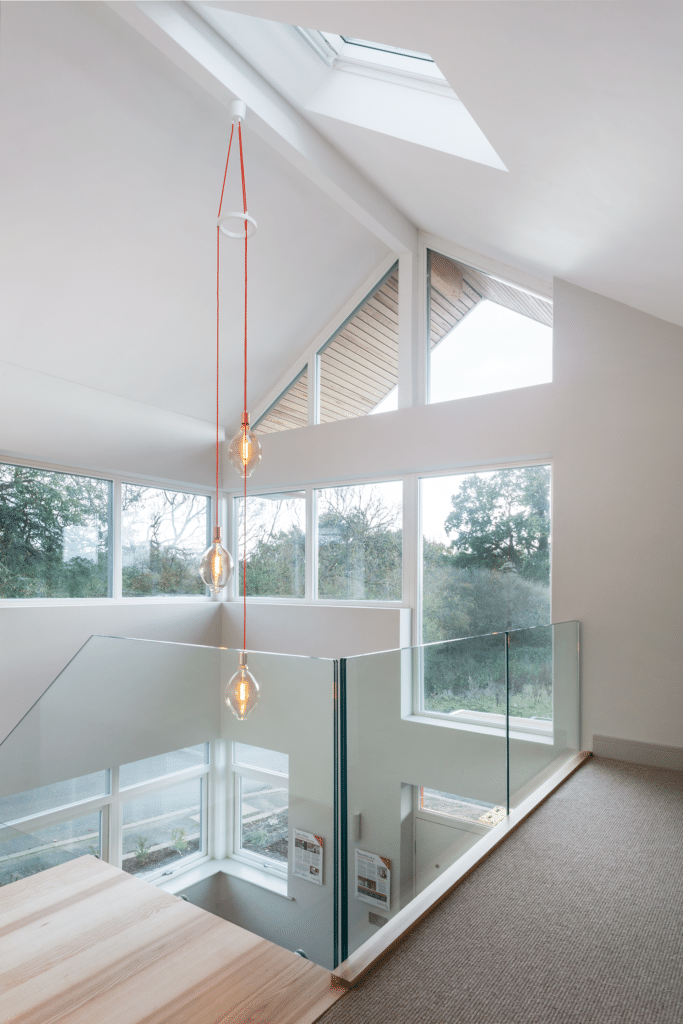

“Timber units tend to offer natural character and slightly better U-values than equivalent aluminium products – although the latter’s slim sightlines made it a close call,” explains Chris. “Kloeber’s high-performance, double glazed timber windows achieve great U-values of 1.3 W/m2K. What’s more, we didn’t need old-school trickle vents, as we were building an efficient new home complete with a mechanical ventilation and heat recovery system to supply fresh filtered air.”

Kloeber offers a dual-colour factory finish. So for the windows and French doors, Build It chose yellow-grey external frames, painted white internally for the ground floor and apex glazing (the rest of the upstairs features clear lacquered pine). The orange FunkyFront door – voted for by Build It’s readers – makes a real statement, and includes a glazed panel to preserve the flow of natural light.

A mix of casement and top-hung windows was selected for easy operation. Laminated glass and good-quality ironmongery come as standard on Kloeber products, so meeting PAS 24 security standards of Building Regs was straightforward.

Most of the windows were pre-ordered based on the technical drawings, with the exception of

the wraparound corner and apex glazing on the front elevation. The margin for error during the main construction phase means even the best builders will struggle to get this kind of detail

100% accurate to the plans, so it’s always best to measure such complex features on site.

Installation therefore proceeded in two stages on site – but in both cases, it was a slick operation, with every member of Kloeber’s crew working in tandem to get every unit level, plumb, foamed and silicone sealed. Windows will only perform as well as they’re fitted, so a high-quality supply and install service can give you real peace of mind.

Book your visit to the Build It Education House and see Kloeber’s windows and doors in action.