Buyer’s Guide: Lime Mortar

Lime mortar is a heritage material that’s been used for centuries for tasks such as bedding or pointing brick and stonework.

Unlike cement, lime mortar is a natural and breathable building product. It’s made with a mix of sand and lime, which acts as a binder, so it’s perfect for both eco-conscious self-builders and renovators taking on period properties.

Why should I use lime?

One of the key advantages of lime mortar is that it’s vapour permeable (or breathable). This means it absorbs moisture from surrounding masonry and allows it to evaporate.

This quality is particularly important for period homes, as they were designed to allow moisture to escape naturally. Using modern, cement-based products on an historic building can cause water to be locked into its fabric, which will in turn lead to damp taking hold.

On new builds, lime’s ‘breathability’ can help to improve the internal environment.

A good lime-based mortar has greater tolerance to movement than cement versions, which comes in handy when working with period homes.

This type of mortar should also be resistant to sulphate attack (the cause of those unsightly stains on some modern brickwork) and is even capable of self-healing if microscopic cracks occur.

Is lime mortar eco-friendly?

Lime products can be a sustainable option – both in production and use. According to the NHBC (National House-Building Council), the production of lime-based mortar involves around 75% to 90% of the energy required to create cementitious versions.

Because lime mortars are soft, it’s relatively easy to clean them off masonry at the end of a building’s life – so there’s more potential to recycle the brick or stone units.

One down side to using lime mortar is that building work proceeds slower than with cement mixes. There’s a number of reasons for this – most notably that the compressive strength of lime products doesn’t develop as quickly and that the mortar won’t set at temperatures below 5°C.

Which type of lime mortar should I choose?

Lime is generally available in two forms: natural hydraulic and non-hydraulic. Although both versions rely on the same key ingredient (limestone) and share many of the same characteristics, they behave differently in use – so you need to be sure you’re choosing the right product for the task in hand.

What is Hydraulic Lime?

Natural hydraulic limes (NHLs) are sold as bagged powders. They’re fast setting (though not quite as quick as cement) so most builders should find them intuitive to use. That makes them a good choice for new build projects.

They are widely available in three grades. Products labelled NHL2 (also known as feebly hydraulic) are typically used internally or for some conservation work.

NHL3.5 (moderately hydraulic) limes are well suited to general building work. A bedding mortar or pointing mix at this grade might constitute 1:2 or 1:3 (lime:sand), plus just enough water for a workable consistency.

Opting for NHL5 (eminently hydraulic) can be ideal where dense materials are being used, such as engineering brick, or severe weather exposure is anticipated.

What is Non-hydraulic Lime?

For heritage projects, the general rule is to match new mortar to what’s already there. This helps reduce the risk of conservation work actually damaging the existing masonry.

In many cases, that will lead you to specifying a non-hydraulic lime as the binder for the mix. This is supplied to site as ‘fat’ putty that needs to be ‘knocked up’ (kneaded and chopped in with sand and aggregates) to create a workable, dough-like consistency – although ready-mixes are now widely available.

It’s usually best to call in a conservation expert to work with this kind of mortar, particularly if you require a special mix.

How much does lime mortar cost?

It’s normally most cost-effective to purchase natural hydraulic limes in bags rather than tubs. You can expect to pay around £10 for 25kg of pre-mixed, just-add-water mortar (complete with sand and aggregates).

Prices for pre-mixed non-hydraulic lime mortars start from around £10 for a 20 litre bucket.

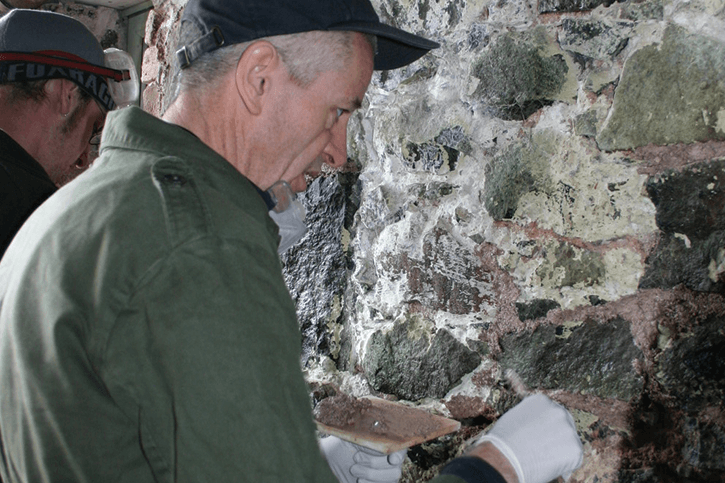

Main image: SPAB runs a number of cources on stonework repair.

Published: Build It magazine May 2013

Login/register to save Article for later

Login/register to save Article for later

Comments are closed.