Kingspan TEK Structural Insulated Panels (SIPs) deliver outstanding fabric and structural performance on this ground-breaking self-build.

When Daniel Frazer purchased a plot of land within the third wave of development, he was committed to creating a distinctive and beautiful home which perfectly met his needs.

“I knew that by using a timber frame construction it would be possible to achieve excellent speed of build, particularly as it can be erected in most weather conditions. Whilst SIPs Panels raised the material costs, they delivered several additional benefits including enhanced airtightness, even faster build speeds and the ability to use the panels to construct the roof.

I eventually chose the TEK Building System after meeting with Point 1 Building Systems. They understood my requirements and provided thorough pre-sales engagement showing how they could deliver some of the more challenging details”.

Daniel Frazer, Homeowner

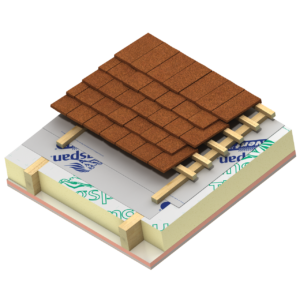

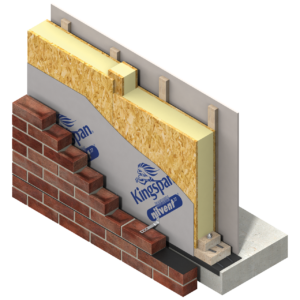

The TEK Building System is formed from rigid insulation panels which are faced with OSB/3. TEK SIPs Panels are pre-cut to each project’s specifications by trained Kingspan TEK Delivery Partners.

This offsite construction approach supports a simple and accurate installation, often allowing SIPs homes to be constructed faster than would be possible with traditional methods.

The outer envelope combines timber and artificial slate cladding in a distinctive modern design which features both flat and pitched roofs.

The first floor has been rotated to provide outstanding views whilst making best use of natural light within the internal space.

Once the design was agreed, they precisely manufactured the SIPs panels before delivering them to site to a carefully scheduled programme.

This offsite construction approach supported a rapid build programme and allowed materials to be stored within the perimeter of the site, and without encroaching into neighbouring plots.

In addition to the steel structural elements, the final package combines 142 mm TEK panels with a 25 mm layer of Thermawall TW55 and Thermapitch TP10 which was fitted throughout the envelope internally.

This design allowed the demanding fabric requirements of the Graven Hill Plot Passport, including wall and roof U-values of 0.15 W/m2K.

Daniel Frazer personally oversaw work to achieve the desired level of airtightness. This work included applying silicone and airtight tape to all junctions other than those between the TEK Building System SIPs.

Steels were shuttered and filled with concrete maintaining the DPC/DPM between concrete and timber. Airtight tape was also applied to all joints between the internal insulation boards.