A 1950s house within a Victorian conservation zone has been cocooned in roof, floor and wall insulation and a contemporary outer shell to create a unique family home.

The site of the aptly named House-within-a-House was once home to a Victorian townhouse, which fell victim to bombing during the Second World War.

Sat rather incongruously amongst its statelier neighbours. When the homeowners bought the property, it was with the vision of creating a new home suited to the needs of a modern family, that also respected the history of the area.

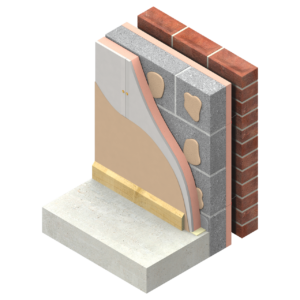

The revised building design adds a third storey with a steeply pitched roof, providing additional living space for the family. A new outer-envelope was built around the existing structure with a layer of cavity wall insulation in between.

Kooltherm products were specified for both the walls and roof of the building envelope. The boards offer leading thermal performance with thermal conductivities as low as 0.019 W/mK.

This helps to keep the ‘building coat’ thin and lightweight, whilst also providing effective protection against the cold.

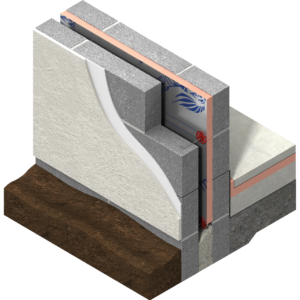

On the lower two levels, 50 mm of Kooltherm K108 was fixed within the cavity formed between the original masonry wall and the new pale brick exterior.

In addition to the cavity wall insulation, a further 57.5 mm thickness of Kooltherm K118 was fixed on the inside of the masonry wall.

Despite the slim thickness of the cavity wall insulation and insulated plasterboard, their excellent thermal efficiency allowed the construction to achieve a U-value of 0.15 W/m2K.

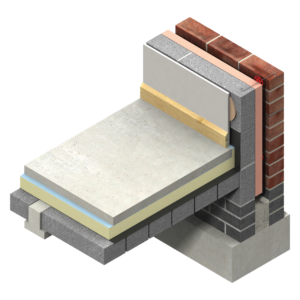

To maintain the clean interior aesthetic, heating on the ground floor is provided through an underfloor heating system.

As part of this construction, a 100 mm thickness of Thermafloor TF70 was first fitted above the concrete floor slab.

By adding a warm coat around the entire structure, the thermally inefficient 1950s dwelling has been turned into a highly insulated, airtight construction.

The thermal performance of the property now vastly exceeds Building Regulations and gives a comparative reduction in CO2 emissions from 61.55 kg CO2/m2 to 16.49 kg CO2/m2.

“Kingspan products are well regarded and high performing and we often refer to Kingspan’s technical guidance to review wall, floor and roof build-ups and ensure that we are achieving the target U-values.

Although the project was not designed to meet any particular energy requirements, the clients’ brief was that they wanted to create an energy efficient and warm home.

Specification of Kingspan products helped to achieve this and we greatly exceeded the energy requirements of building regulations. The clients have found that they typically don’t have to turn on the heating on the upper floors and have low annual energy demands”.

– Tristan Wigfall, alma-nac

Images: Jack Hobhouse