Early Bird Offer! Free tickets to meet independent experts at this summer's Build It Live

Save £24 - Book Now!

Early Bird Offer! Free tickets to meet independent experts at this summer's Build It Live

Save £24 - Book Now!Work slowed right down on site during week seven of the build, thanks mainly to the torrential rain we’ve been experiencing.

We spent a lot of time sweeping pools of water off the floors and willing rain clouds to move on. It’s unfortunate that the wettest week of 2012 arrived at the worst possible moment for our house build, literally days before we’d got the structure watertight, but that’s just one of the potential pitfalls of a self-build project.

On the plus side, at least it showed that the timber frame will stand up well to adverse conditions. And in between the downpours we managed to fit the gable ladders and the pitched roofs of the dormer windows – so we were ready for the roofers to begin the process of getting the felt and temporary battens up on the roof.

1. Our builders put a lot of effort in to maintaining the quality look of the oak, for example by drilling from the back to avoid any visible fixtures and fittings.

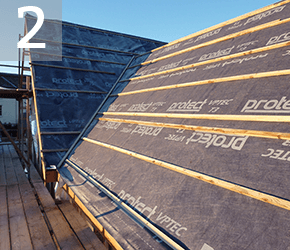

2: Midweek, the roofers arrived to felt and batten the roof. The felt went down with temporary batten tacked on to keep it in place, and the building is now watertight.

Another weekend washout hampered progress, but in the early part of week eight the builders were back on site fixing the fascia and barge board.

Fascia and barge board comes in a range of materials and qualities – from PVCu to various wood options. As we will be having solid wood external joinery I decided to also use it (or more specifically oak) for the fascia and barge board.

There is a lot to be said both for and against the use of solid oak – it should give us a lovely finish to the house, but it does also require a lot more work. For example, rather than being able to order ready-to-fit windows, we had to find a quality joiner to make these, along with all the other oak elements. Everything will need treating and staining as well as careful handling during fitting.

As this will be quite some investment we made sure we did our research and decided to use a local joiner – Andrew Prince Joinery.

I think it’s worth pointing out here the importance of having trusted builders, and the difference they can make to the final look of the build.

Soon the permanent batten will be correctly measured out and secured in readiness for the tiling to commence.