Most self builders are looking to create a comfortable, low-bills living environment, and that means building great insulation and airtightness into the structural fabric.

We’re using insulated concrete formwork (ICF) for the walls and structural insulated panels (SIPs) for the roof, both of which offer excellent performance as standard. Wherever there are risks of gaps that might leak heat, we’re paying close attention to detail to get the building as sealed as possible.

We’re treating pretty much every gap we can get a spray foam nozzle into, and sealing structural joins with membranes and airtightness tapes.

Key areas include the connection between the ICF and SIPs, around windows and other structural openings, and any point where services penetrate the building fabric.

This all adds up to a highly sealed, no-draughts structure. But you need a supply of fresh air for the health of the building and occupants.

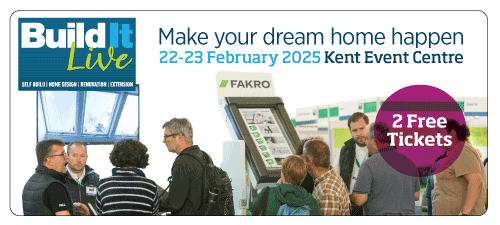

A 3D design for the heat pump ventilation system, showing planned duct locations for the plant room

MVHR (mechanical ventilation and heat recovery) is the default choice for achieving good air quality in a modern, high-spec house. It works by removing stale air from wet zones (such as kitchens and bathrooms) and constantly filtering in a new supply.

At the same time, MVHR extracts up to 95% of the warmth in the expelled air and uses this to pre-warm the incoming, helping to reduce the load on your heating system.

For the Build It House, we’ve decided to take the technology one step further by installing Total Home Environment’s heat pump ventilation (HPV) system.

This will do everything you’d expect from standard MVHR – removing moisture, filtering allergens out of the incoming air, and helping to deal with odours from cooking etc. But it also offers the added benefit of an integral micro air-to-air heat pump.

This heat pump acts like a fridge in reverse, extracting even more heat energy from the exhaust air to boost performance. According to the literature, for every 300 Watts of electricity used to run the pump, you can potentially net 1.5 kWh of heat – giving a COP (coefficient of performance) of 5.

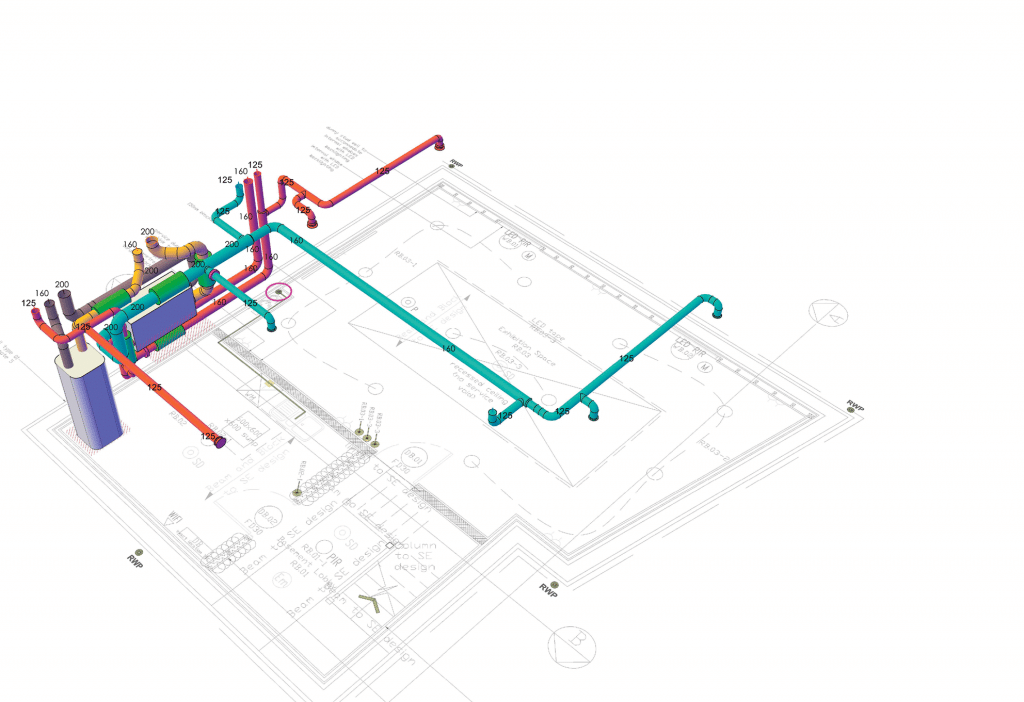

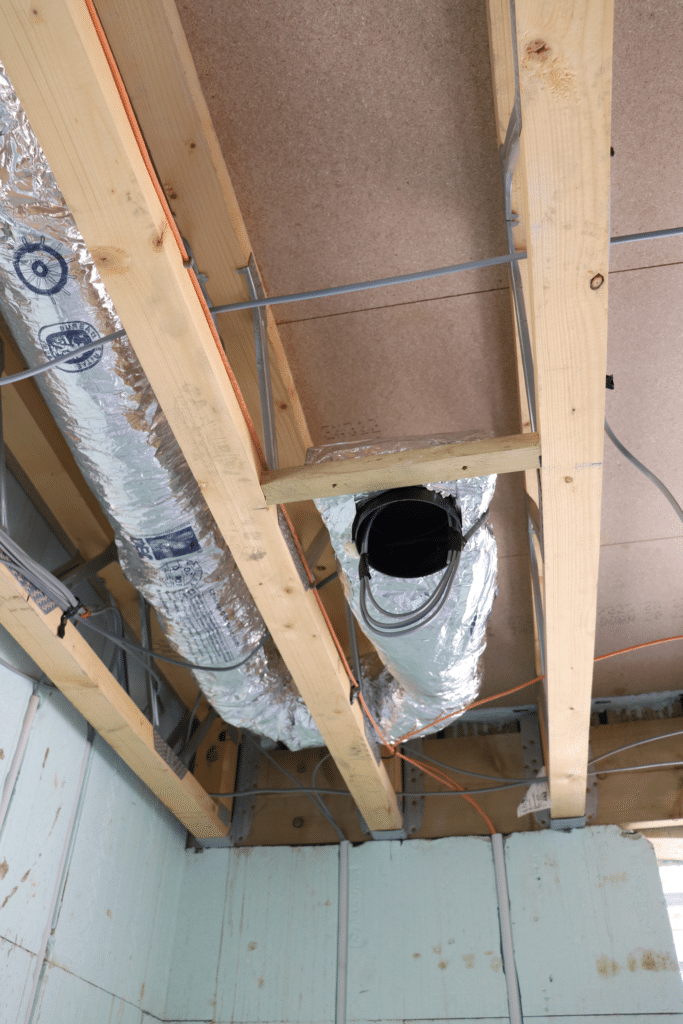

As the ducts are the biggest services running through the building, it makes sense to get them in first. This image shows a silencer above the kitchen

Combine that with the heat recovery element, and efficiency can rise even higher. What’s more, if you need a degree of cooling in the summer months, it can do that too.

We’re installing this alongside Total Home’s HPW 300, a 300L cylinder with its own integrated heat pump that’s able to meet all our domestic hot water requirements. This will also power our underfloor heating.

The HPV and HPW 300 together are Passivhaus-certified, although we’re not actually going for this demanding level of energy performance in terms of the overall design and fabric of the Education House. But we believe our building fabric combined with the systems we’re installing will give us a low-carbon whole house heating solution.

With MVHR, the devil is in the detail. The ducting needs to be carefully planned to minimise turns and bends, and maximise performance. And with pipes up to 200mm in diameter to run into every room, ideally avoiding lots of unsightly boxing, you need patience, experience and open-web joists for your flooring.

So it’s critical to work with a specialist that can provide the complete package. Total Home Environment (THE) is one of the most respected names in the sector, so we were keen to partner with them to demonstrate this innovative technology.

We worked closely with THE to iron out the detail before going on site.

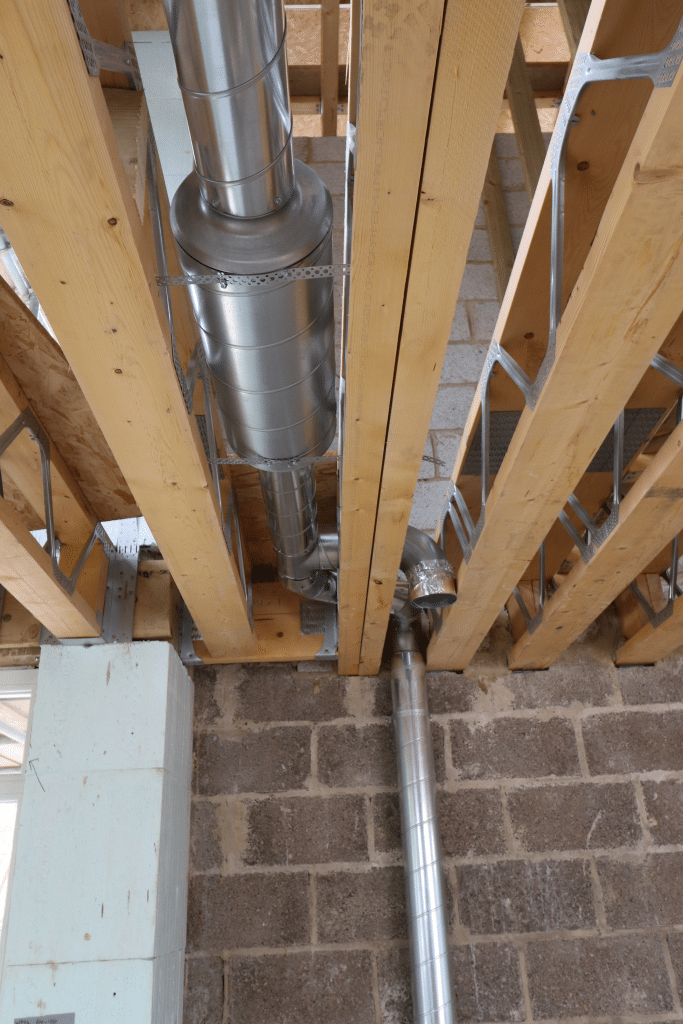

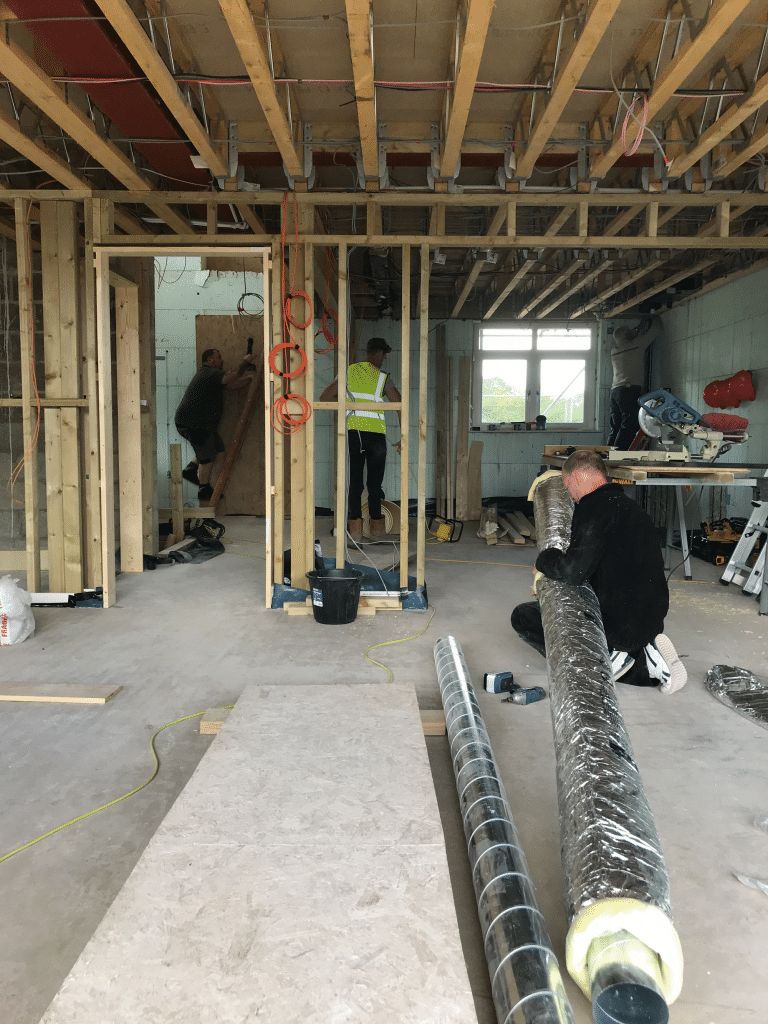

The team insulates a long heated duct run

Total Home’s team provides annotated floor plans and 3D renders, showing everything from extract and heated terminal locations to the diameter and location of ducts, appliance positions and more.

The installer – in our case Peter Inglesant, who has been very willing to share technical info with me – translates the plans into a workable solution.

THE were the first crew on site once the house was watertight, and a lot of work has gone into running the ducting over the past couple of months.

There will always be a challenges to navigate, of course. We might have open-web joists, for instance, but occasionally you can’t place a duct exactly where you’d like to.

We also had a frustrating delay when it turned out one of the concrete beams in the ground floor structure had – totally unforeseeably – been laid directly in the pathway for getting the main extract and exhaust ducts down into the basement plant room. Issues like this inevitably slow progress, but when everyone pulls together there’s always a solution.

The heated duct terminals feature an electric backup to provide a boost of heat if required

On the flip side, we’ve been able to identify some improvements that couldn’t be visualised at the planning stages. For instance, we’ve trimmed back some polystyrene in places to minimise the amount of boxing out, gaining precious internal space.

We’re now at the stage where most of the infrastructure is in place. The final piece of the puzzle is bringing the ducts into the plant room, so we can get Surrey Basements back to totally seal the holes in the internal block wall’s waterproofing layer.

At that point, we’ll be able to board and skim the basement, build our reinforced utility cupboards (onto which the HPV unit will sit) and hook up the system to complete the first fix.

That should all be happening in just over a weeks’ time.

We’ll be leaving the ducts exposed in the basement as part of our Education House mandate; even though there’s more than enough floor-to-ceiling height to allow us to conceal them. To be honest, I quite like the industrial vibe this will bring to the space!