Underfloor heating manifolds are integral to the overall functionality of a new underfloor heating (UFH) system, but how do these work and what do they actually do?

Wet underfloor heating circulates warm water through a network of pipes laid beneath the floor, transforming the entire surface into a radiant heat emitter and creating even coverage across the room. This setup is compatible with various heat sources, including gas boilers and air or ground source heat pumps.

The underfloor heating manifold plays an important role in all water-based arrangements, connecting UFH pipes to the heat source and acting as the central distribution point for the floor conduits. It’s the central hub that each length of pipe goes out from and circles back to, and controls the flow rate of water through the pipes.

Underfloor heating manifolds regulate the temperature and pressure of the underfloor heating system. “Their main purpose is to distribute the large volume of water from the primary heat source into each UFH circuit – the loops of pipe that run under the floor,” says Brendan Hourican, managing director at Omnie. “Warm water enters the manifold and is mixed with cold water to achieve a safe temperature.”

This prevents very hot water – which leaves conventional gas boilers as high as 70°C – from entering your UFH and potentially damaging the floor coverings above. The water flow for UFH typically runs between 35°C and 60°C. The manifold allows you to control room temperatures via a series of electronic actuators. These are connected to individual room thermostats, enabling you to manage the heating schedule within each distinct zone.

House size and the scale of your underfloor heating setup dictates how many manifolds are needed. “Larger properties or multiple floors require more than a single manifold,” says Dan Clist, a professional heating engineer who runs training courses for Nu-Heat’s installers. “The area a single manifold can cover is affected by numerous factors including the floor construction, pipe centres and diameters, plus room sizes and shapes.”

So, how does this piece of equipment function day-to-day? And how can you ensure your underfloor heating manifold performs optimally?

Looking for reliable heating and ventilation suppliers for your self build or renovation project? Browse Build It’s Company Directory of trusted services

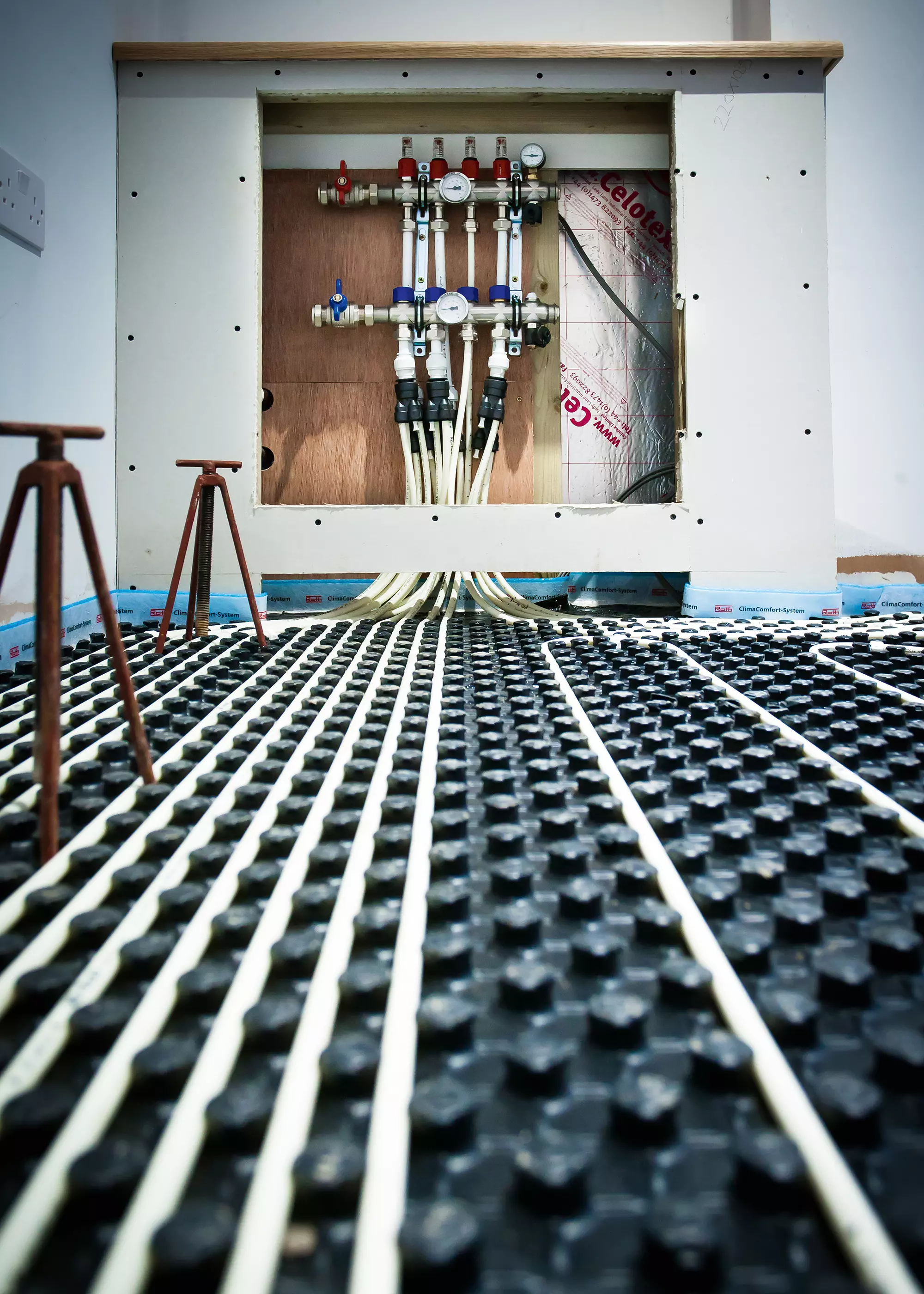

In this LoPro Max setup, supplied and installed by Nu-Heat, you can see the gradual curve of the UFH pipe loops as they are routed from the UFH panel and back to the manifold

To get to grips with how the underfloor heating manifold works, it’s important to understand the core principles that govern how UFH pipework is laid. Warm water streams through snake-like loops, known as circuits.

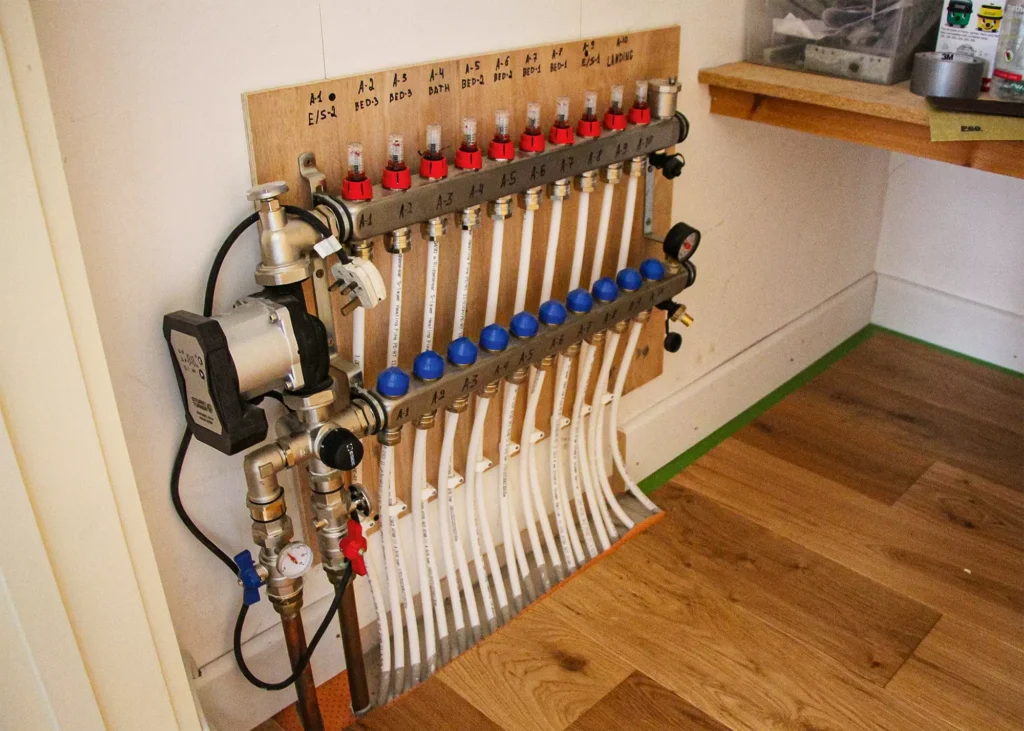

Typically, each room or zone has its own circuit – though large areas may have several. All underfloor heating manifolds come with a series of ports, each connected to the circuit(s) that comprise your system. For example, small areas such as extensions with one or two rooms might be serviced by a manifold with just two ports. Whereas, if you’re kitting out the entire ground floor of your house with UFH, the manifold could have as many as 12 ports.

Learn More: Choosing Heating Systems: Radiators or Underfloor Heating?

Robbens’ nickel-plated brass manifold features auto air vents, pressure and temperature gauges, which show how warm the water is on the supply and return valves

“Actuators on the ports are linked to the thermostat in the room. When a call for heat is recognized, the actuator head opens and allows heat to flow into the zone requiring it,” says Dan. “Once the room has reached the required temperature, the actuator head will close and water will stop flowing.” This means your underfloor heating manifold controls and regulates each loop concurrently. Individual management of each distinct zone is one of the advantages of underfloor heating, as you can avoid warming rooms you spend less time in.

Therefore, to maximise the energy-saving benefits of your underfloor heating manifold system or systems, it’s worth pre-programming the thermostats in rooms where you have UFH to warm up to the desired level of heat at the time(s) of day it’s required.

Most modern underfloor heating manifolds are also fitted with a water pump, which pushes the water around the various circuits at sufficient flow rates for each zone. “Flow meters allow the installer to ensure the system is carefully balanced,” says Brendan.

This 10-port manifold from Omnie was installed in a house in Cambridge to supply multiple zones with underfloor heating

Balancing your UFH is the process of checking the correct water volume is being distributed across the system, so warmth is spread evenly. Large volumes of water typically flow towards shorter pipe circuits, sometimes leaving longer runs of pipework with a lesser flow. For optimum efficiency, your installer creates resistance in short pipe runs and less through longer stretches by adjusting the flow meters on the manifold.

The meters are opened and closed until the desired flow, which is marked on your UFH plans, is achieved. Ask your installer for details on how to balance your system so you can periodically check the levels are correct and the heating can run as efficiently as possible.

Considering an air source heat pump for your self build project? Read more here: Air Source Heat Pumps Explained

CLOSER LOOK Underfloor Heating Manifold MaintenanceThough little ongoing upkeep is required, it’s good practice to perform the following tasks to ensure your manifold functions optimally for many years:

|

Placing your underfloor heating manifold or manifolds in the optimum location is vital for an underfloor heating system to run efficiently. “They should be as central as possible within the UFH area for optimum functionality,” says Tom Edmunds, general manager at Wunda Group. “This reduces the length of pipe required and maximises the area covered by an individual manifold.”

In most cases, it’s best to install your underfloor heating manifold on the same floor as the circuits it feeds, close to the pipework – cupboards, stairwells or voids often provide a convenient spot. “Where possible, they should be placed away from bedrooms as noise from the pump might disturb sleep,” says Tom.

For best results, employ a heating engineer to install your UFH pipework and manifold. Working from your design plans, they will be able to see which port serves which circuit loop in your system. From that, they’ll be able to pinpoint the most efficient path from the manifold to the room(s) you’re heating.

Looking for more heating and home energy advice? Take a look at our collection of Home Energy & Renewables articles

Wunda’s WundaTherm underfloor heating pipework being installed. The system uses an automated manifold to accurately calibrate and balance the entire setup

Each conduit runs along the same route back to the underfloor heating manifold, where it links to the return bar. Once your engineer has connected all the circuits, they will pressure test the system. “While this and the initial set up can be done by someone well-versed in DIY, the final connection must be carried out by a professional,” says Tom.

“During your undefloor heating manifold’s installation, it’s crucial to position the system in an area you can access for maintenance – avoid placing it within plasterboard walls.” The device should sit whereby the heating pipes can exit the floor at a gradual curve below the manifold, with enough room to get the flow pipe behind the bottom bar and fixed to the top flow bar.

Allocating enough space to accommodate your manifold is crucial and is an important detail to factor in during the early design stages of your project. “You’ll need to allow for the required electrical supplies, thermostat wiring and primary pipework,” says Dan. “This will all have an influence on installation logistics and how much space is needed.”