What is Cavity Wall Insulation?

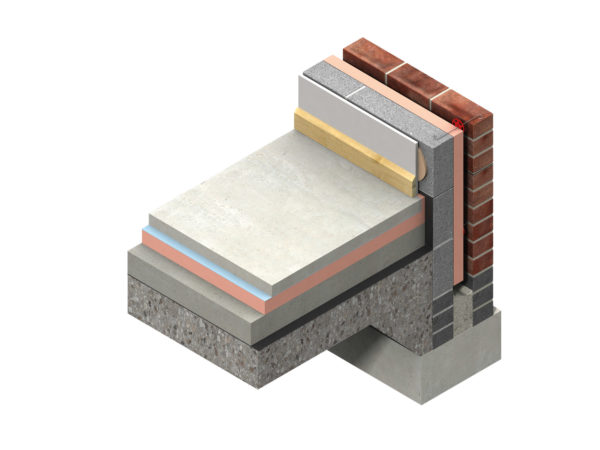

Insulating a cavity wall is a pretty simple concept – slip a little thermally-resistant material into the gap between your walls’ masonry leaves and you’ll reduce heat loss in your home.

But getting the right product for your project involves careful thought.

Cavity wall insulation (CWI) can be in the form of slabs or sheets fitted as the walls go up (the most common option on a self-build), or retrofitted material that’s blown in once the main envelope is constructed (suitable for both new and existing homes).

Whichever method you go for, it’s critical to ensure the masonry leaves are prepared correctly. Any left-over ‘snots’ of mortar, for example, could interrupt the insulation and drastically diminish U-values, making the fabric of your home much less efficient.

Cavity slabs

Sheets of slab insulation are fitted as the walls go up: a typical build process would be inner leaf first to one course over wall tie height; insulation; outer leaf to the top of the insulation; then continuation of the inner leaf. In both cases, the slabs are sized to fit between standard-spaced wall ties (usually 450mm or two block courses in height) in order to aid installation.

Partial-fill is the standard choice for most new developments. It involves leaving a 25mm or 50mm gap between the outer face of the insulation and the external leaf. This has the advantage of reducing the chance of any moisture that does penetrate the outer leaf bridging through to the internal structure. For that reason, the system is required by many local authority building control departments – especially in the UK’s many ‘exposed’ locations.

A typical brick and block wall with a 150mm cavity fitted with 100mm of partial-fill Superwall insulation by Superglass would hit a U-value between 0.25-0.30 W/m2K, for example.

Semi-rigid batts of glass mineral wool or rockwool are the traditional choice. Their flexibility allows them to fit snugly against the masonry as well as knit together at abutments.

Rigid products, such as Kingspan’s Kooltherm 8 for partial-fill or XtraTherm’s CavityTherm for full-fill, offer better thermal performance – allowing you to specify a thinner wall or achieve a better U-value at the same thickness.

Kingspan predicts a result of around 0.15-0.17 W/m2K when using 100mm of Kooltherm 8 in a 150mm cavity. However, rigid products are more expensive up front and installation can require more attention to detail on site.

Full-fill insulation can be slightly quicker to fit, as there’s less need to focus on how the material is held in place. It will also offer slightly better thermal performance over partial-fill for the same wall thickness.

Put simply, with a 150mm cavity you’ll be able to include a full 150mm thickness of insulation; which is likely to net you a U-value of around 0.20 W/m2K on a typical brick and block setup when using a product such as Superwall 36 slab from Superglass. The problem comes in whether your home’s location or external finishes rule out full-fill.

Blown insulation

This type of CWI is either blown or injected into finished walls through strategically-drilled holes. It’s usually specified for upgrading existing homes, but can be successfully used on new builds, too.

There are two main types: loose-fill is of glass mineral or rockwool; while you can also opt for expanded polystyrene (EPS) beads.

One advantage of this method for new developments is that there’s no need for brickies to down tools while slab insulation is installed, as you simply wait until both leaves are up. That can help accelerate the build by around 10% – and also puts your project at less risk of weather delays. The speed benefit can make it an attractive option on sites with multiple developments, such as community self-build projects.

The downside is that finished U-values don’t tend to quite match the equivalent slab insulation – partly due to the difficulty of preventing voids forming in the wall, for example below windows.

A full fill of 100mm of blown mineral wool should achieve a U-value of around 0.27-0.33 W/m2K depending on your choice of blockwork; around 0.02 W/m2K down on what can be achieved with the same thickness of semi-rigid slab. EPS beads can offer a similar U-value to slab insulation.

Login/register to save Article for later

Login/register to save Article for later

Comments are closed.